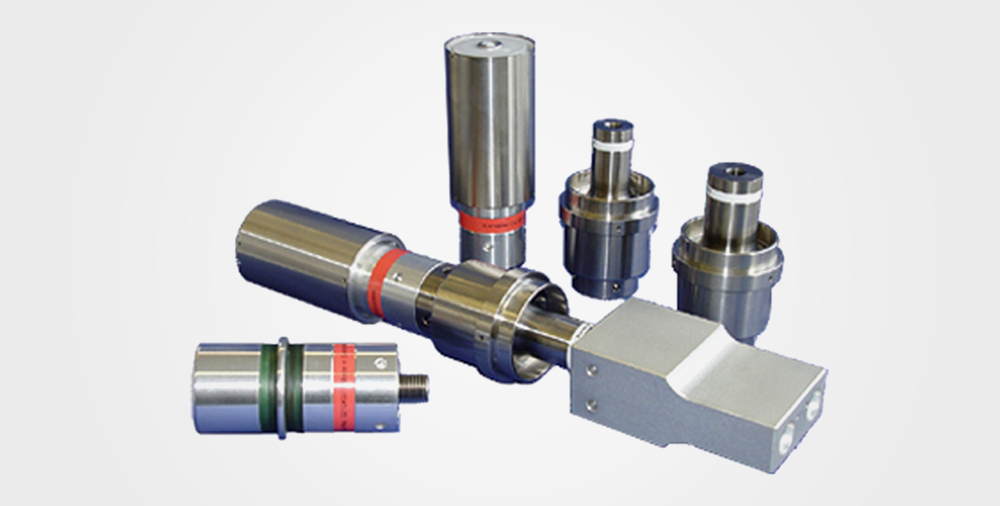

Ultrasonic horns are designed with an FEA (Finite Element Analysis) simulation program that allows our engineers to observe the vibratory action of the horn prior to fabrication. Segmented and adjustable fixtures are built to ensure a secure fit with the molded plastic parts. Contoured fixtures and tools for irregularly shaped parts. Ultrasonic horns are inspected for even amplitude. For added strength and durability, carbide facing or chrome plating is applied. Peripheral devices to clamp, hold and align opposing parts are also available.

Customers can submit application files in the following formats and media Formats (in order of preference):

AutoCAD (DWG, DXF file formats).

Media.

CD-ROM or DVD.

Email (Please ZIP any files larger than 10 meg)

Marketing Engineers Site.

- Container size upto 5 ltrs.

- Martix size l x b x h 1200 x 550 x 350 mm.

- Bag size upto 40" wide and 60" long.

- Speed 1 hrs upto 70bpm.

- Power supply 230 volt.

- Weight 100 kg.

- Height 900 mm.

- Festo pneumatic.

- Adjustable matrix (row and columns).

- Adjustable bag sizes.

- Adjustable height.

- Adjustable plates for pushing matrix.

- Pneumatic based bag tensionary.

- Adjustable conveyor speed.