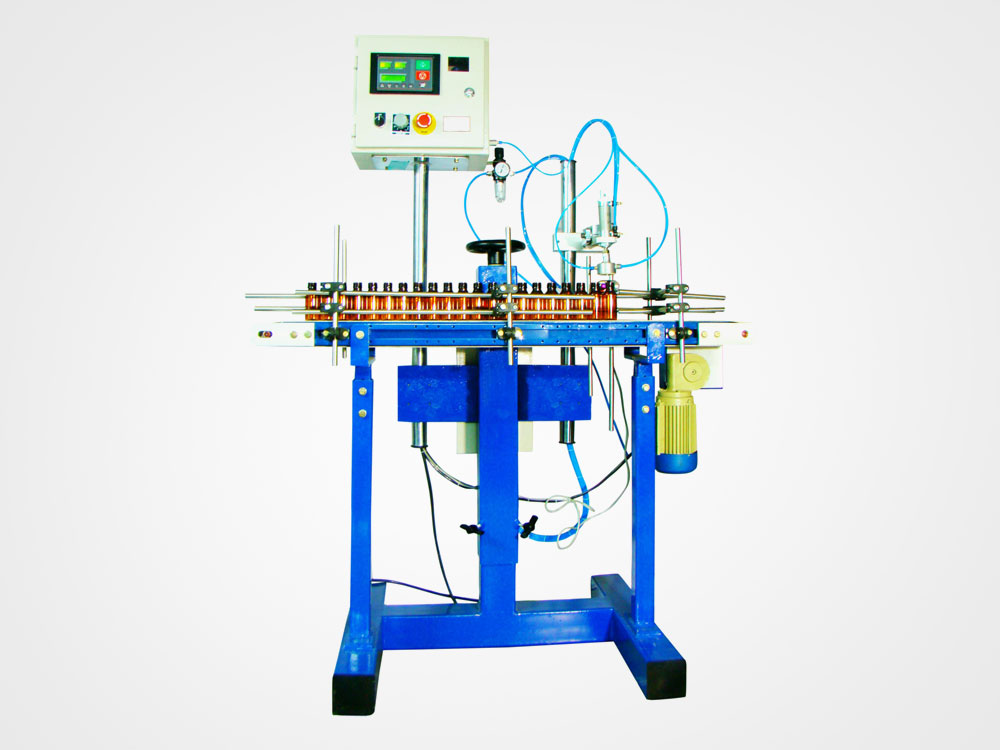

MLD-2010 – single head leak tester using imported microprocessor

LEACON has grown out to be one of the most maintenance free units. This budget unit is capable of testing up to 3000 containers per hour of 50ml, with a vacuum conveyor and servo controlled on a single head and still find 0.17 ~ 0.25mm (0.0007 inch) holes at this rate. This is aimed for use with machines where the annual production rate is up to maximum of 15-20 million bottles per year with 1,2, 3 and 4 cavity production. The unit has high accuracy and is able to find very small holes. If time permits far smaller than 0.17 mm.

- Detects micro holes 0.17 ~ 0.25mm with great repeatability.

- Stores up to 10 different parameter settings and are adjustable during testing.

- Easy height regulation with one hand wheel.

- Reflector less photocell for very quick & exact positioning.

- Festo / SMC & Imported make valves & cylinder.

- Imported Pressure Sensor for accurate & consistent measurement.

- Our own custom built controller with a 2 x 16 character LCD display.

- Integrated 5 digit pass and fail counters.

- Variable speed drive with linear acceleration/deceleration adjustment.

- Test resolution to 0.1 mbar (0.01 kpa).

- Typical test rates -

A. 100 / 250 ml : 2200-2400 / hr

B. 500ml : 1400 – 1600 / hr

C. 1 ltrs : 1000 – 1200 / hr

D. 5 ltr : 350 – 400 / hr

- Supply voltages 230 Vac / 5A single phase.

- Orientation of conveyor form Left to Right.

- Size of Conveyor: 200mm x 1200 mm long.

- Height of Conveyor: 950-1100 mm range.

- Volume of Containers: 50 ml - 6Ltrs.

- Working air pressure 5 kg/cm2.

- Max. input air pressure 9 kg/cm2.

- Weight 130 kgs.

- Max Container size: 450 mm high, 300 mm long, 150 mm wide, neck up to 45 mm with standard head.

MLD - 2020 – single head leak tester using indigenous microprocessor

"LEACON" Leak Tester is a micro controller based system manufactured and designed to meet today's challenging technical as well as commercial environment. LEACON is used on blow molding machine or packing lines. The test conducted in this machine guarantee the highest Precision, Consistency and Reliability for leak free bottles.

LEACON has grown out to be one of the most maintenance free units.

- Detects micro holes 0.17 ~ 0.25mm with great repeatability.

- Stores up to ONE parameter settings and are adjustable during testing.

- Easy height regulation with one hand wheel.

- Reflector less photocell for very quick & exact positioning.

- Festo / SMC & Imported make valves & cylinder.

- Imported Pressure Sensor for accurate & consistent measurement.

- Our own custom built controller with a 2 x 16 character LCD display.

- Integrated 4 digit pass and fail counters.

- Variable speed drive with linear acceleration/deceleration adjustment.

- Test resolution to 0.2 mbar (0.02 kpa).

- Typical test rates -

A. 100 / 250 ml : 1600-1800 / hr

B. 500ml : 1100 – 1300 / hr

C. 1 ltrs : 800 – 900 / hr

D. 5 ltr : 250 – 300 / hr

- Supply voltages 230 Vac / 5A single phase.

- Orientation of conveyor form Left to Right.

- Size of Conveyor : 200mm x 1200 mm long.

- Height of Conveyor : 950-1100 mm range.

- Volume of Containers: 50 ml - 6Ltrs.

- Working air pressure 5 kg/ cm 2.

- Max. input air pressure 9 kg/ cm 2.

- Weight 130 kgs.

- Max Container size: 450 mm high, 300 mm long, 150 mm wide, neck up to 45 mm with standard head.

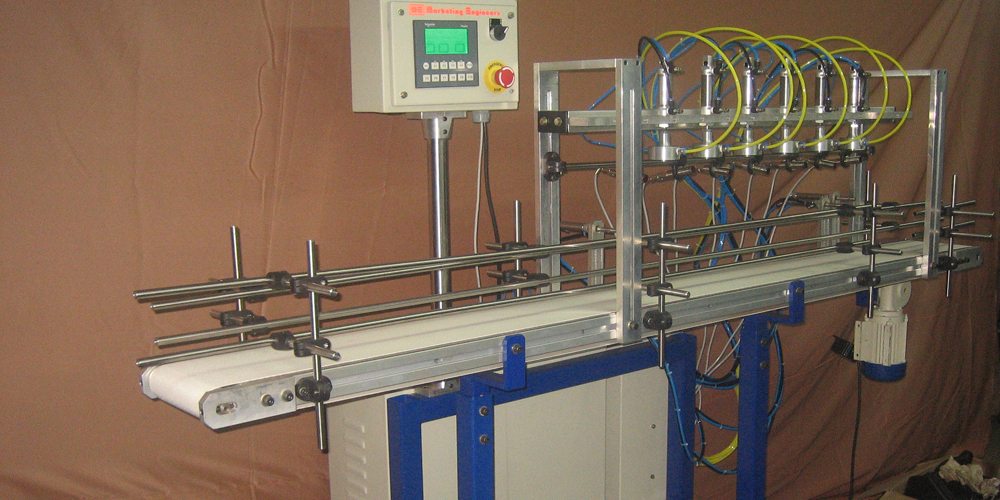

- Detects micro holes 0.35 ~ 0.50mm with great repeatability.

- Stores up to 10 parameter settings and are adjustable during testing.

- Festo / SMC & Imported make valves & cylinder.

- Imported Pressure Sensor for accurate & consistent measurement.

- Our own custom built controller with a 2 x 16 character LCD display.

- Integrated 5 digit pass and fail counters.

- Audio and video alarm for rejected drums

- Variable speed drive with linear acceleration/deceleration adjustment.

- Test resolution to 0.1 mbar (0.01 kpa).

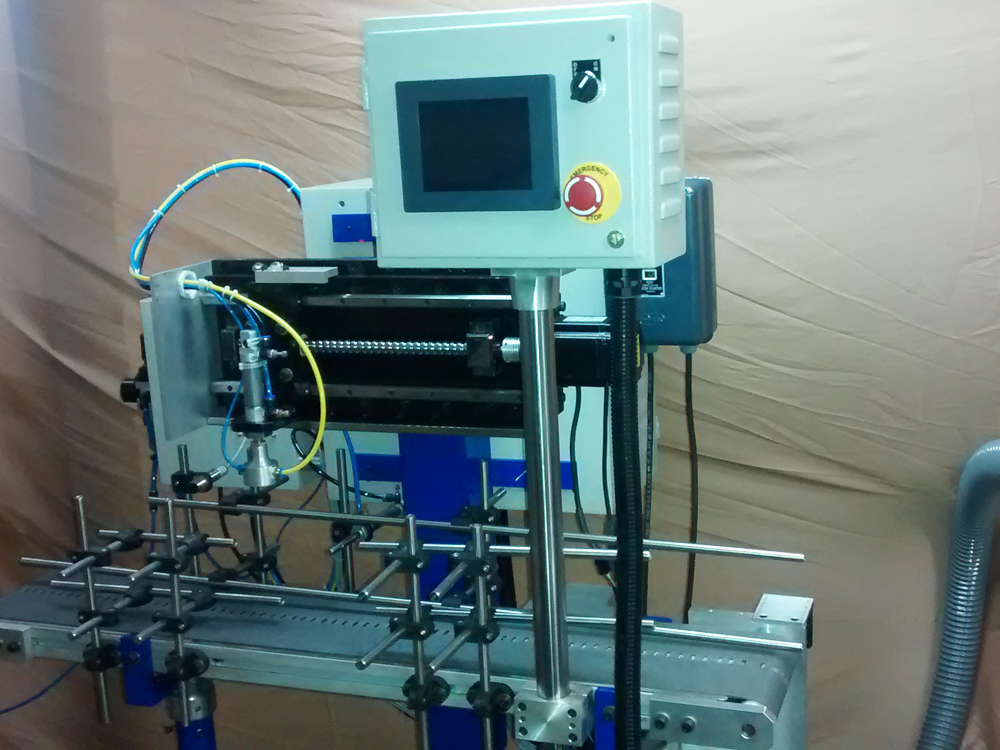

- Detects hole size of 0.25mm.

- Touch screen for easy operation.

- Counter system for rejection operation.

- Input / Output status on the diagnostic page

- Force parameter to check the output.

- Error / Fault message display.

- Stores upto 10 different parameter settings and are adjustable during testing.

- Software (built in) counter for Accepted/Rejected bottles/containers.

- AC drive for adjustable speed of the conveyor.

- Adjustable test heads

- Festo & Imported make valves & cylinder.

- Reflectorless photocell for very quick & exact positioning.

- Imported Pressure Sensor for accurate & consistent measurement.

- Approx Speed : 1 Ltr :: 1700/hr :::::: 500ml ::2000/hr

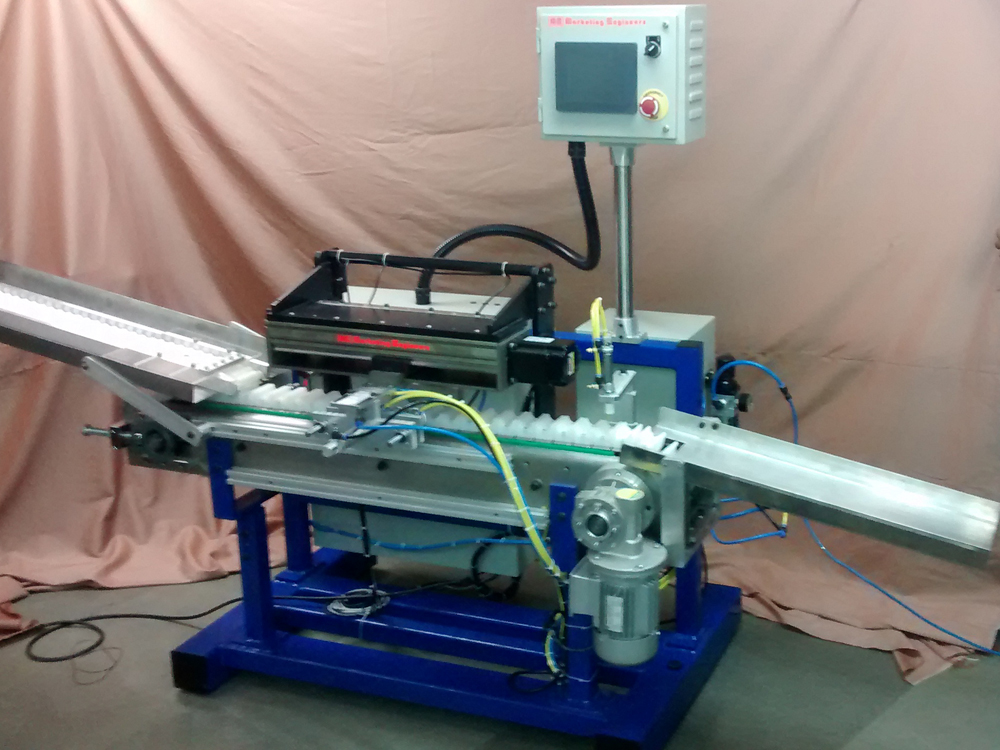

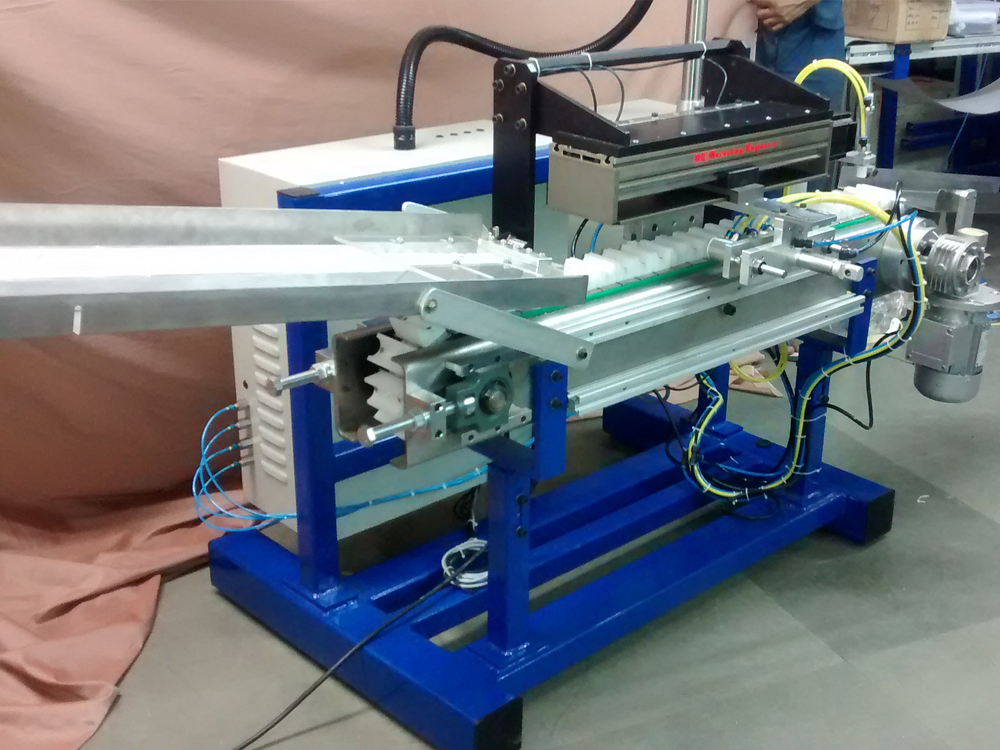

MLD-2000 – Multihead, Leak Tester

The new MLD-2000 series is a result of years of experienceby Marketing Engineers in the leak testing of plastic containers. The MLD-2000 is designed to test containers from 100ml to 5000ml.

- Detects hole size of 0.25mm.

- Touch screen for easy operation.

- Counter system for rejection operation.

- Input / Output status on the diagnostic page.

- Force parameter to check the output.

- Error / Fault message display.

- Stores upto 10 different parameter settings and are adjustable during testing.

- Software (built in) counter for Accepted/Rejected bottles/containers.

- AC drive for adjustable speed of the conveyor.

- Adjustable test heads.

- Festo & Imported make valves & cylinder.

- Reflectorless photocell for very quick & exact positioning.

- Imported Pressure Sensor for accurate & consistent measurement.

- All Adjustable test heads.

- Power Supply : Single Phase 230Vac

- Working Air Pressure : 6 Bars

- Air Consumption : 1-2 CFM

Special Purpose Machine –SPM